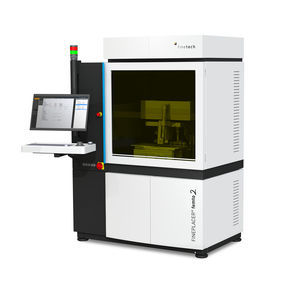

Ручная установка для компоновки электронных блоков FINEPLACER® pico 2для микросборкидля полупроводниковой промышленностидля использования в медицине

Добавить в папку «Избранное»

Добавить к сравнению

fo_shop_gate_exact_title

Характеристики

- Режим функционирования

- ручная

- Применение

- для микросборки, для использования в секторе коммуникаций, для использования в медицине, для датчика, для полупроводниковой промышленности, для быстрого прототипирования, для исследований и разработок

- Другие характеристики

- высокой точности

- Точность размещения

3 µm

Описание

Multi-Purpose Manual Die Bonder

The FINEPLACER® pico 2 is a versatile manual die bonder with placement accuracy down to 3 µm. Quick to set up and easy to operate, it is ideal for rapid product development and prototyping in R&D labs and universities.

Designed for flexibility, the system supports numerous technology and process modules as well as application-specific tools. Users can integrate third-party functionalities and customize the system as needed. The modular architecture allows on-site retrofitting throughout its service life.

Getting started is effortless.

A high-resolution vision alignment system with adaptable fields of view and adjustable RGB illumination ensures optimal contrast between components and substrates, making manual alignment easy and reliable.

The spacious working area accommodates 300 mm wafers and supports batch processes. A high-resolution bonding force module with a wide force range enables precise handling of various components.

With the intuitive IPM Command bonding software, process creation is seamless. Users can focus on core application tasks while minimizing operating errors. The software offers extensive parameter control for process optimization.

Following the “Prototype to Production” approach, the FINEPLACER® pico 2 features a unified hardware and software platform, ensuring a smooth transition from development lab to production.

Combining application flexibility, technological diversity, process reliability, and compatibility with Finetech’s automated production bonders, it delivers excellent return on investment and is a natural starting point on the path from concept to final product.

ВИДЕО

Каталоги

Product Flyer FINEPLACER® pico 2

4 Страницы

Салоны

Вы сможете встретиться с этим поставщиком на выставке(-ах)

Расширенный поиск

- Ремонтная станция

- Установка для компоновки электронных блоков

- Ремонтная станция горячим воздухом

- Автоматическая ремонтная станция

- Ремонтная станция для BGA

- Автоматизированная установка для компоновки электронных блоков

- Установка для компоновки электронных блоков высокой точности

- Ремонтная станция для печатной платы

- Установка для компоновки электронных блоков перевернутый кристалл

- Ремонтная станция для SMD

- Эпоксидная установка для компоновки электронных блоков

- Установка для компоновки электронных блоков для микросборки

- Установка для компоновки электронных блоков для крепления кристалла

- Полностью автоматическая установка для компоновки электронных блоков

- Эвтектическая установка для компоновки электронных блоков

- Ремонтная станция для LCD

- Установка для компоновки электронных блоков multi-chip

- Ручная установка для компоновки электронных блоков

- Полуавтоматическая установка для компоновки электронных блоков

* Цены указаны без учета налогов, без стоимости доставки, без учета таможенных пошлин и не включают в себя дополнительные расходы, связанные с установкой или вводом в эксплуатацию. Цены являются ориентировочными и могут меняться в зависимости от страны, цен на сырьевые товары и валютных курсов.