- Производственные машины

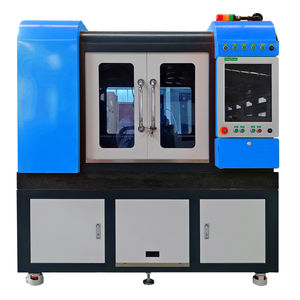

- Станок для резки

- Станок для резки волоконный лазер

- Golden Laser Co., Ltd

Станок для резки волоконный лазер GF-1530для сталидля нержавеющей сталидля алюминия

Добавить в папку «Избранное»

Добавить к сравнению

Характеристики

- Технология

- волоконный лазер

- Обрабатываемый материал

- для стали, для нержавеющей стали, для алюминия, для меди, для латуни, для титана, для углеродистой стали

- Обработываемое изделие

- для листа, для металлического шланга, для металлической мебели, для двери, для металлических панелей, для витражей

- Тип управления

- ЧПУ

- Комбинированная функция

- для гравировки, для маркировки, для сверления, для пробивки отверстий, для профилирования, для скашивания кромок, для контура

- Применение

- для промышленного применения, для автомобилестроения, для бойлеров, для использования в авиации, для электронной промышленности

- Другие характеристики

- высокоэффективный, высокоточный, высокоскоростной, сверхточный, CE, FDA, с высокой пропускной способностью, с водяным охлаждением, SGS, высокая мощность, для стальной конструкции, для больших деталей, с серводвигателем

- Ход Х

1 550 mm

(61,02 in)- Ход Y

3 050 mm

(120,08 in)- Мощность лазера

МИН.: 700 W

1 000 W, 2 000 W

МАКС.: 3 000 W

Описание

The model GF-1530, GF-2040 laser machine adopts double ball screw closed-loop system and Cypcut Controller. High processing accuracy and high working efficiency during high speed cutting, with the cutting area 1500mm* 3000mm; 2000mm* 4000mm, which can cut 22mm carbon steel and 10mm stainless steel.

Applicable Materials:

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate, metal pipe and tube, etc.

Applicable Industries:

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Main Features:

Open design provides easy loading and unloading

Single working table saves space

Drawer style tray makes easy collecting and cleaning for the scraps and small parts

Gantry double driving structure, high damping bed, good rigidity, good speed and acceleration

The world’s fiber laser source and famous electronic components to ensure machine superior stability

Technical Parameters:

Cutting software: CYPCUT

Laser source: nLIGHT/ IPG/ Raycus fiber laser resonator

Laser power: 700w 1000w 1500w 2000w 2500w 3000w

Processing area: L3000mm* W1500mm; L4000mm* W2000mm

Maximum acceleration: 1.2g

Positioning accuracy: ±0.05mm/m

Repeat position accuracy: ±0.03mm

Electric power supply: AC380V 50/60Hz 3P

ВИДЕО

Каталоги

medium power laser cutting machine

1 Страницы

medium power laser cutting machine

1 Страницы

Другие изделия Golden Laser Co., Ltd

Sheet Metal Laser Cutting Machine

Расширенный поиск

- Система резки

- Система резки для металла

- Система резки ЧПУ

- Станок для резки с лазером

- Станок для промышленной резки

- Автоматическая система резки

- Высокоточная система резки

- Система резки для листа

- Высокоскоростная система резки

- Система резки волоконный лазер

- Система резки для труб

- Система резки для пластиковых материалов

- Сверхточная система резки

- Система резки для алюминия

- Система резки для тканей

- Станок для резки SS

- Система резки для автомобилестроения

- Система резки CE

- Система резки для бойлеров

- Система резки для пластин

* Цены указаны без учета налогов, без стоимости доставки, без учета таможенных пошлин и не включают в себя дополнительные расходы, связанные с установкой или вводом в эксплуатацию. Цены являются ориентировочными и могут меняться в зависимости от страны, цен на сырьевые товары и валютных курсов.